Environmental Conservation Initiatives

In order to help protect the global environment, we are taking company-wide action toward environmental conservation

Howa Sangyo considers the global environment in its management practices, and we are active on environmental conservation company-wide, recognizing that this is essential to the sustainable development of the company.

Reduce environmental impact

Due to their volatility, the volatile organic compounds (VOC) contained in printing ink often end up as atmospheric gas, and this has been a cause of smog and particulate pollution in recent years. With the amendment of Japan’s Air Pollution Control Act, Howa Sangyo has been pro-active not only in lowering its emissions substantially below baseline values, but also in introducing reduced energy consumption in its factories nationwide.

Howa Sangyo believes that reduction of energy consumption is also connected to Japan’s "Act on the Rational Use of Energy" (energy saving law) and the "Law Concerning the Promotion of Measures to Cope with Global Warming," and thus represents part of our corporate social responsibility. We aim not only to respond to a variety of packaging needs but also to be a eco-friendly and people-friendly company with low environmental impact.

Solar power generation

(Hikata factory)

A solar power generation system based on an on-site PPA model*1 has been installed as part of measures to address climate change as well as from the stance of effective use of resources through renewable energy. All electricity generated by this facility is supplied to the plant.

(Hikata factory)

A solar power generation system based on an on-site PPA model*1 has been installed as part of measures to address climate change as well as from the stance of effective use of resources through renewable energy. All electricity generated by this facility is supplied to the plant.

*1 PPA (Power Purchase Agreement) model: A service in which a power producer installs solar power generation facilities on a customer's premises and supplies the generated electricity to the customer.

Energy-saving initiatives

(Narashino factory & Hikata factory & Kyoto factory)

Equipment was installed not only to remove VOC constituents contained in the plant’s dry exhaust but also to absorb exhaust heat for reuse within the plant. We are pro-actively moving ahead with energy-saving challenges at the factory.

(Narashino factory & Hikata factory & Kyoto factory)

Equipment was installed not only to remove VOC constituents contained in the plant’s dry exhaust but also to absorb exhaust heat for reuse within the plant. We are pro-actively moving ahead with energy-saving challenges at the factory.

Materials recycling

VOC discharged into spherical activated carbon is lowered to a concentration below the baseline value before emission.

VOC discharged into spherical activated carbon is lowered to a concentration below the baseline value before emission.

Thermal recycling

〈(Hikata factory)

〈(Hikata factory)

High-performance incinerator with exhaust heat boiler generates steam for printing press drying and to humidify the factory.

Naturally, this is a green system with no emission of dioxins and complete removal of dust and soot.

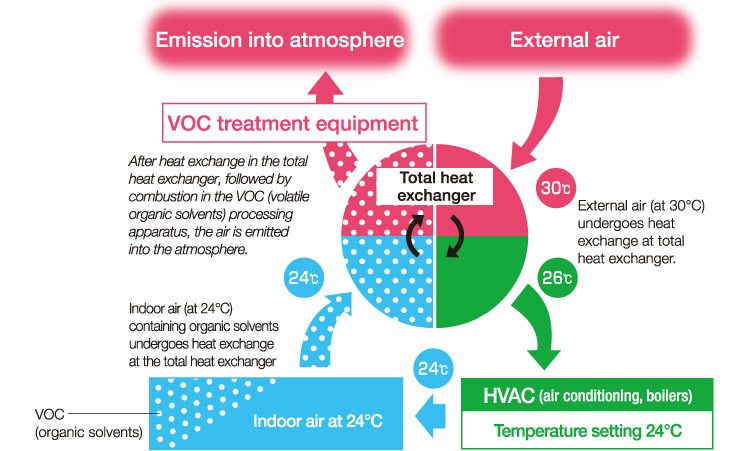

Total heat exchanger mechanism

(Hikata Factory & Kyoto factory)

By lowering the external temperature, we reduce the energy (gas and electricity) used for air-conditioning. This is how we work to save energy and reduce environmental impact.

*Summer example used.